Mastering moisture in mass timber

08.07.2024

Written by Sanja Buncic

Associate Director

Mass timber structures are renowned for their sustainability, strength, and aesthetics.

However, they face a critical challenge: moisture management.

Timber is hygroscopic, meaning it easily absorbs moisture from the environment. This can lead to fungal decay and other issues if not managed properly.

Typically, timber used in products like Cross-Laminated Timber (CLT) and Glue-Laminated Timber (GLT) is kiln-dried to prevent pest or fungal attacks.

However, improper handling during construction, exposure to precipitation, or high humidity can allow water to penetrate the timber, leading to degradation and compromised structural integrity.

Two key issues in moisture management

You need to be aware of two main risks:

- Moisture ingress

This is a significant concern for mass timber buildings. While the timber’s moisture content in protected interior environments is low, manufacturing and construction techniques can sometimes create pathways for moisture, leading to long-term issues. - Biological threats

Fungi and moulds are primary threats. Mould thrives on sugars in the sapwood in high-humidity environments and can cause health concerns. Decay fungi can degrade structural integrity if moisture content stays high, posing safety hazards.

To mitigate these risks, you must understand the sources of moisture ingress and implement strategies to prevent prolonged exposure. Address potential weaknesses in design and construction, such as joints and interfaces where water can accumulate.

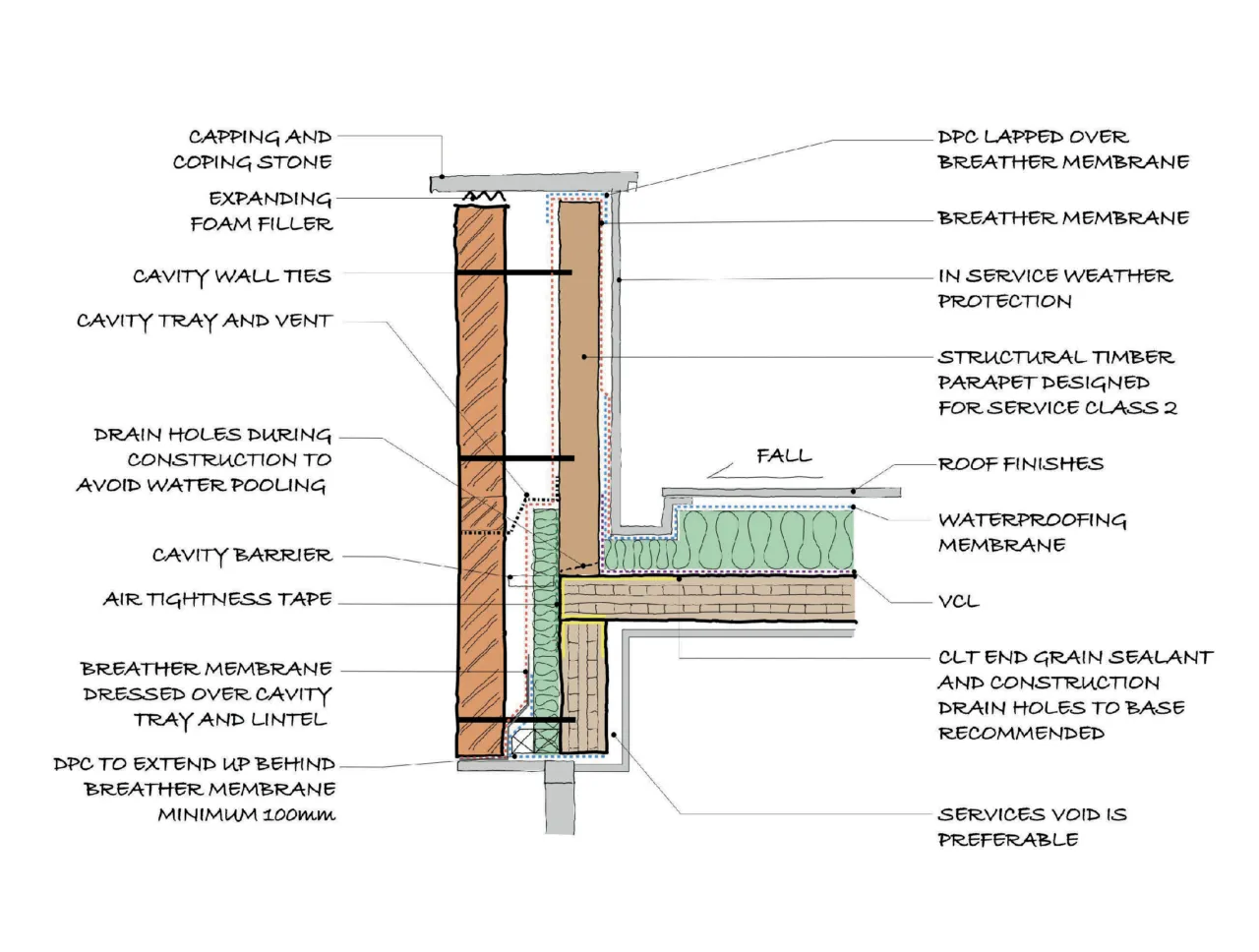

Proper detailing, careful site handling, and protective membranes are essential for managing these challenges effectively.

Three prevention strategies

Effective moisture management involves a combination of thoughtful design, careful site handling, and precise installation practices.

- Design and manufacture phase

- Clearly define service classes and incorporate features that protect timber from moisture

- Raise timber elements from ground level, ensure proper drainage systems, include falls to flat roofs and design walls and roofs to avoid condensation

- Use appropriate protective membranes and vapour barriers

- Ensure end grain sealers and vapour membranes are factory applied before members are delivered to site

- Transport, on-site protection and installation

- Deliver timber just in time for the installation limiting onsite storage duration

- Protect timber from precipitation and high humidity during transport, storage and construction. Use plastic wraps, tarps, and temporary tents if necessary

- Regularly inspect and address any signs of water ingress during construction

- Avoid water traps by detailing roofs for sufficient runoff and ensuring proper drainage outlets

- Seal joints and interfaces meticulously to prevent water penetration

- Define sequence of work to allow for drying

- In-use protection and monitoring

- Clearly define strategies for escape of water and floods, maintenance and repair

- Monitor structure for ingress of water and act swiftly

These measures will significantly enhance the longevity and resilience of mass timber buildings, ensuring they remain safe and durable for years to come.